Mechanical characterization of Biopolymers

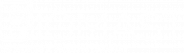

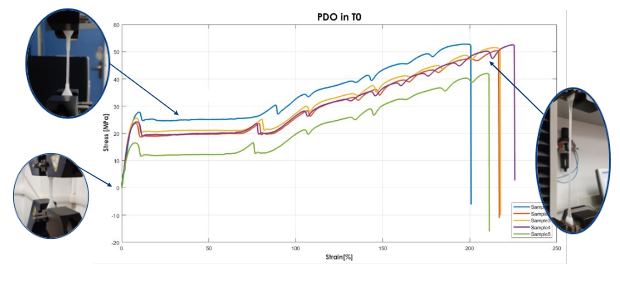

Mechanical characterization of biopolymers is essential for deeply understanding the behaviour of the material intended for biomedical applications. It aids in selecting the material capable of meeting all the requirements of the object of study. In our laboratory, we perform various types of mechanical tests, including those following standards such as ISO 527. We are mainly focused on uniaxial stress tests, stress-relaxation tests, and fatigue tests. The results of these tests allow us to extract fundamental parameters for determining mechanical properties such as Young’s modulus, ultimate stress, and yield stress, as well as more complex parameters that can be used to study constitutive models capable of best describing the material under examination.

Curve Plot (Polydioxanone)

Uniaxial Tension Test (Polymer Blend PLA/PCL)

Mechanical characterization of Soft Tissues

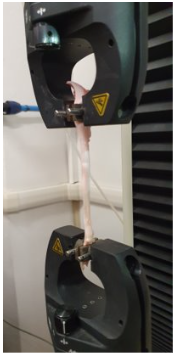

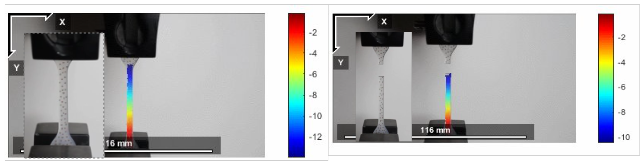

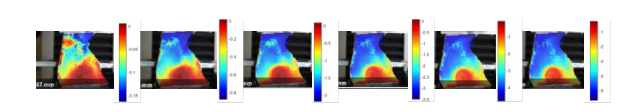

To design medical devices for biological tissues, the first step is to understand the mechanics of the tissue you are working with. Once the animal tissue that most closely resembles the target human tissue is identified, we test its laboratory to evaluate its strengths and weaknesses through tests such as uniaxial tension tests and stress-relaxation tests. From the mechanical curves obtained and the characterizing mechanical parameters, we search for mathematical models that can most accurately replicate its mechanical behavior. We also use the Digital Image Correlation technique to assess the distribution of strains occurring during experimental tests and compare them with finite element analysis.

Bovine intercostal tissue

Porcine tendon tissue

3D Printing and Prototyping

In the laboratory, CAD software such as 3DRhinoceros and SolidWorks are used for the design and optimization of device geometries. Once the design is confirmed, prototypes are created using 3D printing through SLA (Stereolithography) FormLabs. We have a wide range of resins with very different mechanical properties, allowing us to print everything designed in CAD. This step is essential in the research phase to evaluate which geometry and mechanical properties best meet the defined requirements.

3D Printing

Digital Image Correlation (DIC)

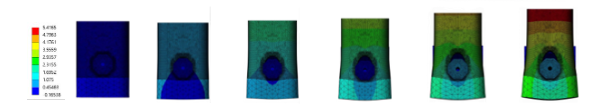

Constitutive modelling and Finite Element Analysis

In the laboratory, we study various constitutive models suitable for polymeric materials and biological tissues, starting from easier models like Mooney-Rivlin, Yeoh, and Ogden for the behaviour of hyperelastic materials, to more complex models like the Bergstrom-Boyce model and the Three-Network-Model for polymers characterized by a plastic component of behaviour. We also study fiber-reinforced models, more suitable for biological tissues characterized by a matrix component and a fibrous component. These models are essential in finite element analysis of the complex biological tissue-device system, as they more accurately understand the interactions and mechanical behaviour.

Finite Element Analysis

Digital Image Correlation (DIC)